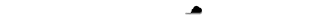

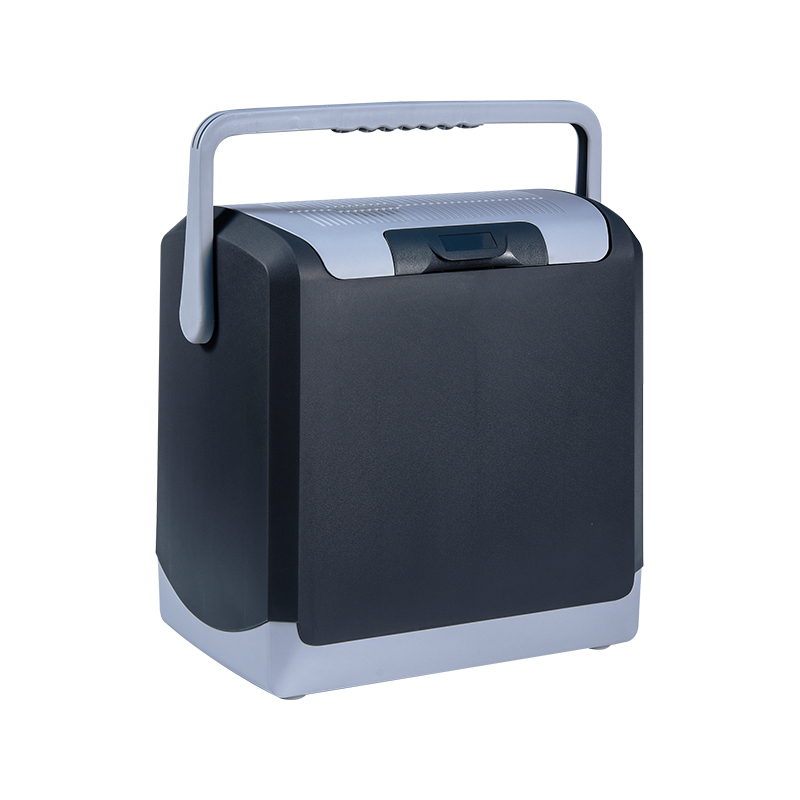

How to ensure the stability of Fast Cold Distribution Thermoelectric Cooler with Warmer?The operational stability of

Fast Cold Distribution Thermoelectric Cooler with Warmer is the key to ensuring its efficient and long-lasting operation. In order to ensure the stability of this equipment, comprehensive considerations need to be made from multiple aspects, including design and manufacturing, material selection, operating environment, and maintenance.

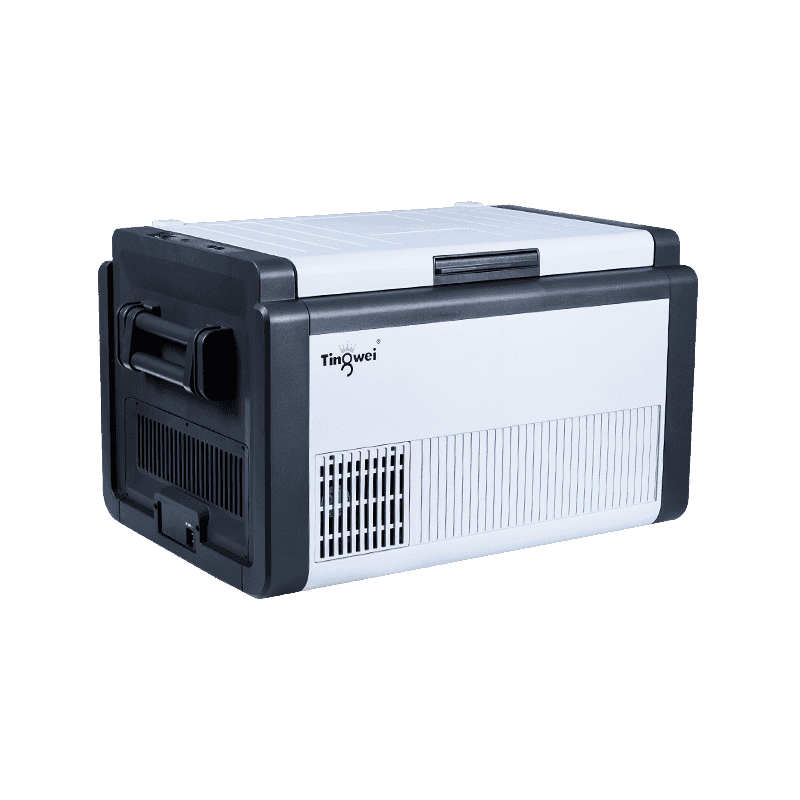

First of all, design and manufacturing are the basis for ensuring the stability of the equipment. During the equipment development stage, various possible usage scenarios and conditions should be fully considered, and sufficient simulation testing and verification should be conducted. By optimizing the structural design, circuit layout and heat dissipation system, the equipment's ability to withstand shock, vibration and temperature changes is improved. At the same time, high-quality parts and materials are selected to ensure the durability and reliability of the equipment.

Secondly, material selection is crucial to ensure device stability. Thermoelectric materials are the core component of Fast Cold Distribution Thermoelectric Cooler with Warmer, and their performance directly affects the cooling and heating effects of the equipment. Therefore, thermoelectric materials with excellent thermoelectric properties, high stability, and long life should be selected. In addition, materials with good thermal conductivity, corrosion resistance and wear resistance should also be selected for the cooling system, shell and other parts of the equipment to ensure stable operation of the equipment in harsh environments such as high temperature and high humidity.

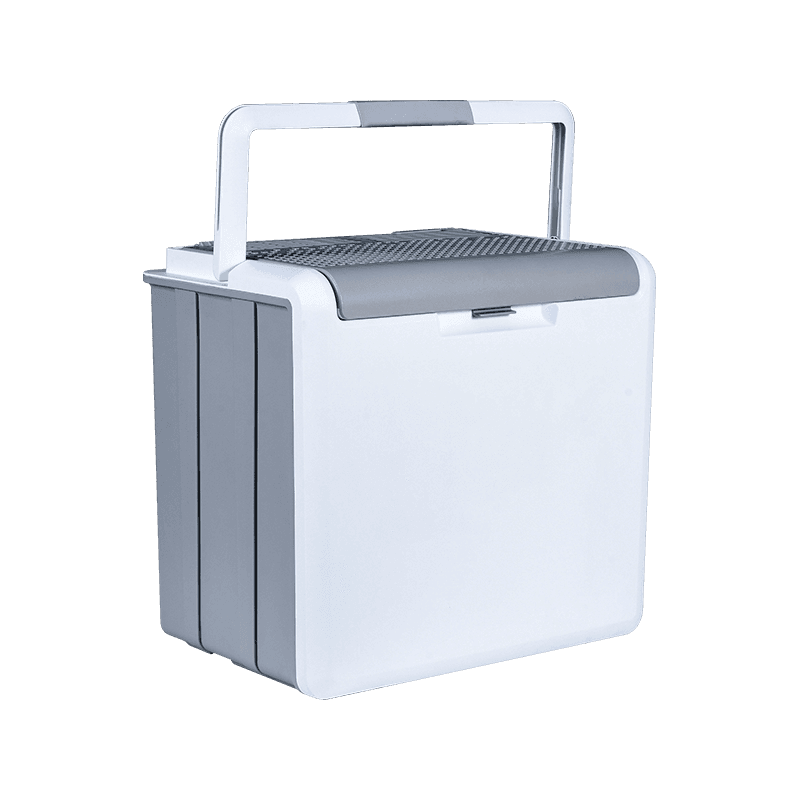

In addition to design and materials, the operating environment is also an important factor affecting the stability of the equipment. The equipment should be installed in a stable, dry, well-ventilated place, away from direct sunlight and rain erosion. At the same time, make sure there is no excessive dust and debris around the device to avoid affecting its heat dissipation effect. During use, care should also be taken to avoid strong impact and vibration on the equipment to avoid damage to its internal structure.

In addition, maintenance is also an important means to ensure the stability of the equipment. Clean and inspect the device regularly to ensure that its surface and heat dissipation holes are free of dust and debris. The circuits and components of the equipment should also be inspected and replaced regularly to ensure their normal operation. At the same time, during use, attention should be paid to observing the operating status and temperature changes of the equipment, and detecting and handling abnormal situations in a timely manner.

Finally, the application of intelligent control and fault diagnosis systems can also improve the stability of the equipment. Through intelligent control systems, precise control and automatic adjustment of equipment temperature can be achieved, reducing human operation errors and uncertainties. The fault diagnosis system can perform real-time monitoring and early warning of the operating status of the equipment, helping users discover and deal with potential problems in a timely manner to avoid equipment shutdown or damage due to faults.

Ensuring the stability of the operation of Fast Cold Distribution Thermoelectric Cooler with Warmer requires comprehensive measures from multiple aspects. By optimizing design and manufacturing, selecting high-quality materials and parts, providing a good operating environment, and performing regular maintenance and intelligent control, the stability and reliability of the equipment can be effectively improved to ensure that it can perform at its best during use.

English

English 中文简体

中文简体

2025-07-18

2025-07-18