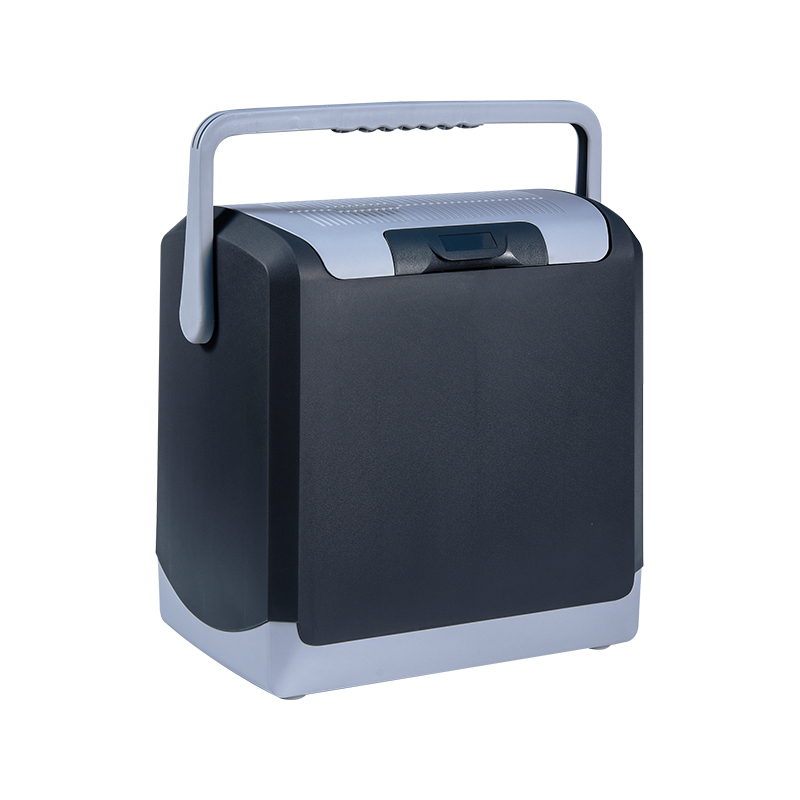

What Maintenance is Required for the Car and Home Dual-Purpose Two Way Ventilation Thermoelectric Cooler?Maintaining the

Car and Home Dual-Purpose Two Way Ventilation Thermoelectric Cooler is essential to ensure optimal performance, longevity, and safety of the device. While thermoelectric coolers generally require less maintenance compared to traditional compressor-based systems, regular upkeep is still necessary to prevent malfunctions and prolong the lifespan of the cooler. Here's a comprehensive guide on the maintenance tasks required for the Car and Home Dual-Purpose Cooler:

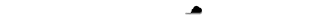

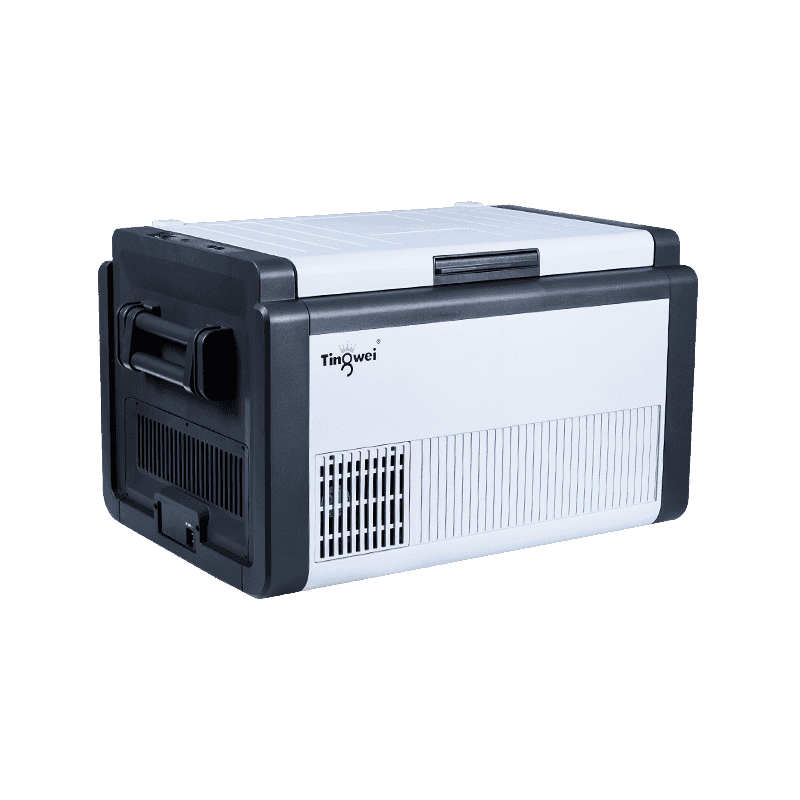

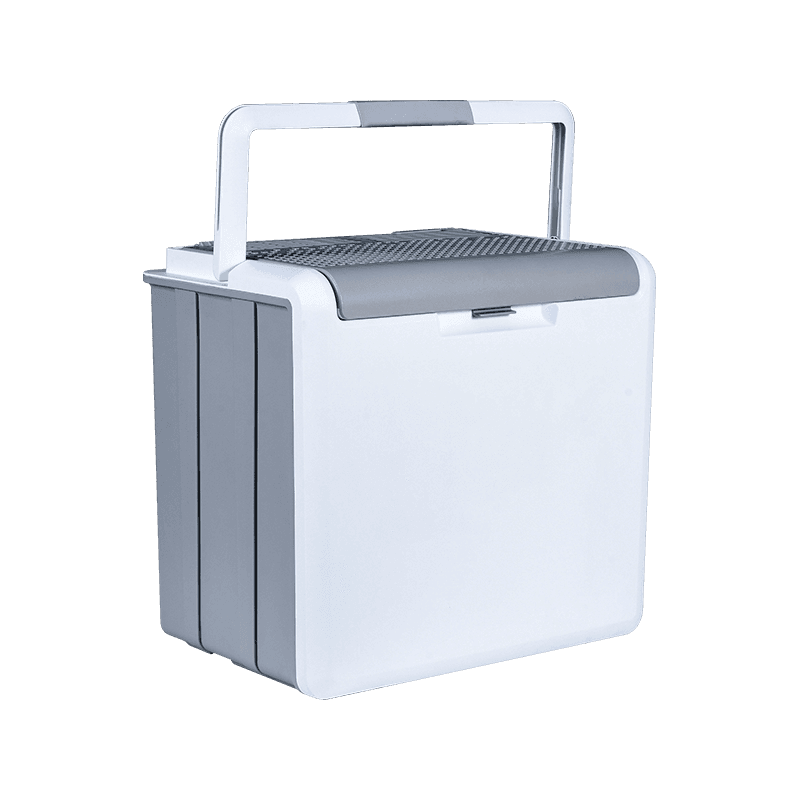

Cleaning:Regular cleaning is crucial to prevent dust, debris, and other contaminants from accumulating on the cooler's components, which could hinder airflow and thermal efficiency.

Exterior Cleaning: Wipe down the exterior surfaces of the cooler with a damp cloth to remove dust and dirt. Avoid using harsh chemicals or abrasive cleaners that could damage the finish.

Interior Cleaning: Periodically remove the cooler's cover or access panels to access the interior components. Use compressed air or a soft brush to gently remove dust and debris from the fan blades, heat sinks, and other internal parts.

Ventilation Ports: Ensure that ventilation ports are free from obstructions, such as leaves or insect nests, which could impede airflow. Use a vacuum cleaner or compressed air to clear any blockages.

Regular inspections help identify potential issues early and prevent costly repairs or replacements down the line.

Electrical Connections: Inspect electrical connections for signs of corrosion, loose wires, or damage. Tighten loose connections and replace any damaged wires or connectors to ensure reliable operation.

Thermoelectric Module: Check the thermoelectric module for signs of damage or deterioration, such as cracks or discoloration. Replace the module if any abnormalities are detected to maintain optimal cooling and heating performance.

Fan Operation: Test the fans to ensure they are functioning correctly. Listen for unusual noises or vibrations, which could indicate a problem with the fan motor or blade assembly.

Temperature Sensors: Verify that temperature sensors are accurately detecting temperature changes. Calibrate or replace sensors as needed to maintain accurate temperature control.

Some components of the cooler may require lubrication to reduce friction and ensure smooth operation.

Fan Bearings: If applicable, lubricate fan bearings according to the manufacturer's recommendations. Use a light machine oil or silicone-based lubricant to prolong bearing life and reduce noise.

Moving Parts: Apply a small amount of lubricant to moving parts, such as hinges or sliding mechanisms, to prevent corrosion and ensure smooth operation.

Filter Replacement:

If the cooler is equipped with air filters, regular replacement is necessary to maintain air quality and prevent dust buildup.

Filter Inspection: Check the condition of air filters regularly. Replace filters if they are dirty, damaged, or clogged with debris.

Replacement Schedule: Follow the manufacturer's recommendations for filter replacement intervals. In high-traffic or dusty environments, filters may need to be replaced more frequently.

Calibration ensures that temperature settings and control mechanisms are accurate and reliable.

Temperature Calibration: Periodically calibrate the cooler's temperature control system to ensure that set temperatures correspond accurately to actual temperatures inside the cooling chamber.

Control Adjustment: Verify that temperature control settings are functioning correctly. Adjust controls as needed to maintain desired temperatures.

Professional Maintenance:

For more complex maintenance tasks or repairs, consider consulting a professional technician with experience in thermoelectric cooling systems.

Professional Inspection: Schedule periodic inspections by a qualified technician to assess the condition of the cooler and identify any potential issues.

Repairs and Replacements: If components are damaged or malfunctioning, enlist the services of a professional technician to perform repairs or replacements. Attempting DIY repairs could void warranties or cause further damage.

English

English 中文简体

中文简体

2025-07-18

2025-07-18